DOWEL BAR PRODUCTS AND APPLICATIONS

Epoxy Coated Dowel Bar can be used in any type of concrete exposed to rust conditions.

Although Dowel bar increases the initial cost, it lowers the Life Cycle Cost. Thus, more durable structures emerge.

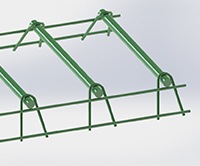

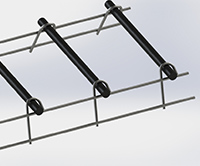

Dowel Bar significantly increases the performance of the production in pavement, concrete road, apron, etc. manufacturing and extends the service life of the structure.

Dowel Bar minimizes deformations such as splitting, distortion, and collapse that may occur in concrete.

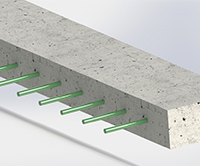

Half of the length of this bar is embedded in one of the concrete slabs and the rest is adhered to the adjacent slab. One end of the rod is kept free for movement during expansion and contraction of the slab depending on temperature change.

Dowel Bar is used to transfer load from one plate to another while allowing axial thermal expansion along the round shaft axis. Stainless Dowel Bar is usually produced from flat round material. They provide a durable, corrosion resistant solution to joints in concrete or other structural applications. There is a Dowel Bar suitable for most requirements, available in a variety of sizes, material grades and strengths.

We have dowel bar manufacturing according to the specifications below.

Carbon Steel: ASTM A615/615M: Gr40, Gr60, Gr75

Stainless steel: 304/304L, 316/316L, S31803, S32205, S32304

-Dowel Bar significantly increases the performance of the production in pavement, concrete road, apron, etc. manufacturing and extends the life of the structure.

-Although Dowel bar increases the initial cost, it lowers the Life Cycle Cost.

-Epoxy coated dowel bars has greater performance for corrosion resistance

Regbar, as well as industry experience in manufacturing for more than 20 countries outside of Turkey and field supervision / consultation provides. Regbar manufactures and applies many construction equipment such as dowel bar, anchorage, reinforcement sleeve etc.

DOWEL BAR PRODUCTS AND APPLICATIONS